Posted on June 27 2019

Toyota Kirloskar Motor celebrates 20 years of its journey in India

[Collaborates with Supply Chain partners to achieve sustainable development]

27th June, 2019 Bangalore: Toyota Kirloskar Motor, a subsidiary of the leading automobile manufacturer globally, is celebrating 20 years of offering ever better cars to its customers in India. Toyota’s focus in India has been steady towards sustainable growth and to remain competitive with best of safety, comfort, luxury, quality and after sales services, through globally acclaimed models, to further enrich customer trust & confidence.

Toyota truly believes that a company alone cannot be sustainable, unless it takes along its supply chain. To enhance flexibility, TKM has been collaborating more with supplier partners & continuously striving to work with its stakeholders, contributing towards the goal of sustainable development.

In line with TMC’s guiding principles & management philosophy, TKM has adopted its policies, values and code of conduct for the entire supply chain covering the suppliers, dealers, contractors and vendors.

Mr. Masakazu Yoshimura, Managing Director, Toyota Kirloskar Motor said, “At Toyota, we believe that for businesses to succeed in this competitive and dynamic environment, we need to have a robust ecosystem of suppliers, vendors and partners. The objective is for the suppliers to develop strategies from mid to long term perspective and become globally competitive to expand business operations both in India & overseas.

TKM along with its supplier partners believes that sustainability should be imbibed throughout the supply chain, beginning with the concept followed by development and then continuing through all phases of production and finally customer distribution, as ‘Customer First’ remains at the core of our philosophy.”

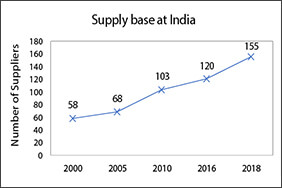

With a network of 155 supplier partners and 7 onsite suppliers, TKM is continuously working towards improving product quality, reducing costs and rationalizing manufacturing through measures that include promoting localization and improving logistics.

To ensure that our suppliers are aware and on-board with the sustainability culture, TKM has taken up various initiatives dedicated to suppliers that focus on and address social and environmental objectives.

Toyota believes working with suppliers, involving and empowering them is the key for maintaining long term supplier relationship. Toyota always works hand in hand with supply base & supports the suppliers in area of Safety, Quality, Productivity, & Human Development thus creating a continuous WIN – WIN business Model.

A. TKM PURCHASING PRACTICES

- TKM has established purchasing policy to ensure fair ground for all supplier partners which communicates corporate values, culture with suppliers and set compliance targets to ensure conformance to all applicable laws and regulatory requirement.

- The General Purchase Agreement(GPA) signed by suppliers provides guidelines on principle of operation and focuses on complying with safety & environmental standards with customer satisfaction as the primary objective.

- TKM established the Green Purchasing Guidelines in accordance with the Global challenge 2050 and taking the changing environmental regulation into consideration with the intent of reducing the environmental footprint throughout the supply chain.

B. Contribution to Indian Automotive Sector

1. Supply Base Development – Parts & Components:

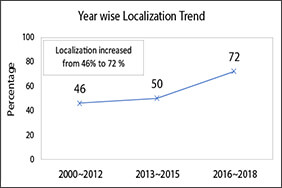

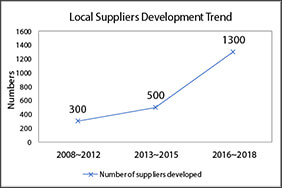

Toyota in a period of 20years, has developed a Global supplier base and Supply chain in India. Toyota’s Supply Chain is well connected on Toyota’s Principles of Toyota Production System (TPS), namely (JIT & Jidoka). Toyota focuses on increasing the number of supply base through localization of parts & components, thereby providing an opportunity for local suppliers to be transformed into world class manufacturing, with strong focus on Quality and Cost at par with Global standards.

2. Supply Base Development - Indirect Purchasing:

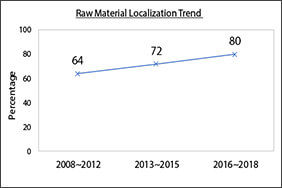

Along with the establishment of Parts & Component suppliers, Toyota also handles all Indirect purchases (Procurement of facilities to aid in manufacture of end product) and raw material buying (Paint, Sealer, NVH material etc.). This has facilitated in improving raw material localization, increasing the number of local suppliers across India.

All these suppliers are periodically evaluated, based on the Toyota standards, thereby ensuring a Quality Product to end Customers.

In addition, indirect buying also audits the vendors on adherence of labor regulations, facilities, renumeration to stay legally compliant.

C. DEVELOPING STABLE, SUSTAINABLE & COMPETITIVE SUPPLY BASE

Toyota believes suppliers to be partners in business operations & aims to transform supply base to be globally competitive. Toyota works hand in hand with the suppliers to enhance overall performance of shop floor, helping them achieve Delivery & Quality targets consistently. These gemba development initiatives develops ownership & pride among suppliers to stay profitable even during tough business conditions.

Unique Supplier Development Initiatives

To ensure sustainable business operations, TKM is continuously working to enhance the overall competitiveness of suppliers for future sourcing and export business opportunities. The supplier development model is based on 2 pillar (Focused Gemba Support & Cost Competitiveness) approach to ensure sustainable performance & profits.

1. Focused Gemba Support

Toyota supports suppliers to establish shop floor management with high level of safety, environment to meet quality & delivery targets consistently and there by achieve smooth operations.

1.a. Development of Safe Workplace for Suppliers.

Safety is always given First priority at Toyota. With ‘Safety First’ as our foundation, Toyota supports suppliers to achieve zero Fire & Fatal Accidents, through implementing safety systems & procedures, there by establishing risk free sustainable supply base. Toyota also focuses promoting safety across indirect buying area like Construction projects, Annual maintenance projects – Facilities, Safety training for commutation drivers to spread safety culture.

1.b. Strengthen Shop Floor Management to achieve Stable Gemba.

i. Quality Enhancement -

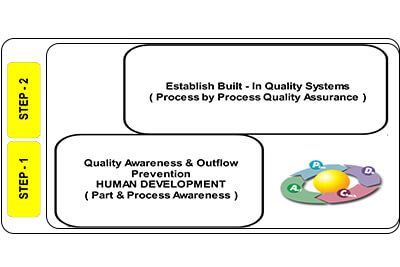

To inculcate Toyota Quality culture in suppliers, Toyota adopts step by step approach of enhancing quality awareness through Human Development & establishing built in quality systems through Process assurance.

ii. Productivity Enhancement –

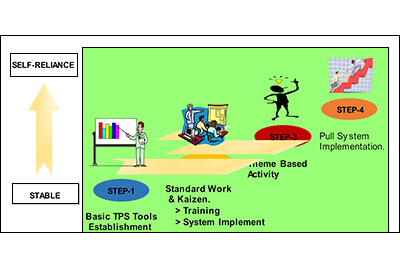

To achieve consistent delivery performance at suppliers, Toyota establishes fundamental TPS tools, Standardized Work & Kaizen there by reducing inventory & shorten the production lead time.

2. Building Cost Competitiveness

Toyota supports suppliers to enhance profitability through reduction of manufacturing cost by eliminating waste at various process across the value chain. TPS Tools are used to identify potential waste (Muda, Mura & Muri) and kaizen is initiated to make the process simple & better. Cost Management Systems are deployed to visualize the gaps in cost and action is initiated at the management level to optimize cost.

3. Human Resource Development at Suppliers.

Toyota’s objective is to build a strong, stable & sustainable gemba at supplier, through effective transfer of Toyota culture. The company focuses on various human resource development initiatives to strengthen the overall shop floor capability and there by developing self-reliant suppliers.

3.a. Supplier Gemba Leader Program(SGL)

One of the important programs is to develop a Toyota Man (Supplier Gemba Leader) at every supplier. This program is aimed at developing supplier middle management for one year on Toyota Manufacturing principles.

One year classroom and on the job training is provided on various skill sets to improve Safety, Quality and Cost Performance and then the activity is reviewed on monthly basis and based on it they are certified by Toyota Management as ‘Toyota Man’.

3.b. Supplier Management Development Program ( SMDP )

SMDP is a Management Development Program introduced to develop Supplier Plant Heads to deepen the understanding on Toyota way of manufacturing & HRD so that it strengthens the supplier partners to be self–reliant and win out, even during volatile business conditions.

The above Plant Management program focuses strongly on -

- Toyota Business Practices (TBP)for problem solving.

- Toyota Production System (TPS)for lean manufacturing.

- Monozukuri Innovation for cost competitiveness.

D. Supplier Connect - Toyota Kirloskar Supplier Association ( TKSA )

Toyota Kirloskar Supplier Association ( TKSA ) is a unique forum through which Toyota and Supplier partners work to share best practices through ONE TEAM – ONE GOAL model towards enhancing competitiveness Globally. 70% of the Suppliers are the members of this association as on 2019. The vision is to make all suppliers become Globally Competitive by enhancing fundamentals to meet company Targets in terms of ‘Safety First, Quality Must’ with Customer First Approach.

E. Global Kaizen Summit

Global Kaizen Summit is an international forum for sharing & learning best practices among Toyota Affiliates. Toyota continues to focus on enhancing the overall competitiveness of their Suppliers towards Global level for future sourcing and creates many platforms including Global Kaizen Summit for Suppliers to show case their Kaizen & best practices to other Toyota affiliate companies.

F. Contribution to Society:

Toyota Purchasing along with CSR team also focuses on various social activities, like Environment Day promotion at Local Community, Safety Education to School Children etc. These activities are also conducted at Suppliers along with respective Regional Supplier Top Management. Key activities include Green initiatives like, Resource conservation and Ecosystem development through Sapling Plantation.

| Company name | Toyota Kirloskar Motor Private Limited |

| Equity participation | TMC: 89%, Kirloskar Systems Limited (Mr. Vikram S. Kirloskar): 11% |

| Number of employees | Approx. 6,500 |

| Land area | Aprox. 432 acres (approx.1,700,000 m2) |

| Building area | 74,000 m2 |

| Total Installed Production capacity | Upto 3,10,000 units |

| Established | October 1997 (start of production: December 1999) |

| Location | Bidadi |

| Products | Innova, Fortuner manufactured in India. Prado, Land Cruiser and Prius imported as CBUs. |

| Installed Production capacity | Upto 1,00,000 units |

| Start of Production | December 2010 |

| Location | On the site of Toyota Kirloskar Motor Private Limited, Bidadi |

| Products | Corolla Altis, Etios, Etios Liva, Etios Cross, Camry & Camry Hybrid |

| Installed Production capacity | Upto 2,10,000 units |

| Toyota Kirloskar Motor Pvt. Ltd. | Creation |

|---|---|

|

Ananya Bhattacharjee Email : ananya_bhattacharjee@toyota-kirloskar.co.in |

Archita Deb Mobile : +91-63622-84691 Email : archita.deb@creation.io |