Harmonizing with the Environment

Globally, Toyota has indicated a strong and diverse commitment to the pursuit of harmonious growth through its technically advanced and environment-friendly products. There have been relentless efforts in the crucial fields of mobility, city transportation, resources, society and environment, through research & development.

Protecting the environment has always been a priority at TKM, starting with the eco-friendly engines that are manufactured for the Toyota vehicles, to the advanced technology that is used for purification or recycling of waste water at the plant. Apart from this, the plant at Bidadi, Karnataka, is surrounded by a green belt, meets high environmental standards and has achieved the ISO 14001 certification in its very first year of operations.

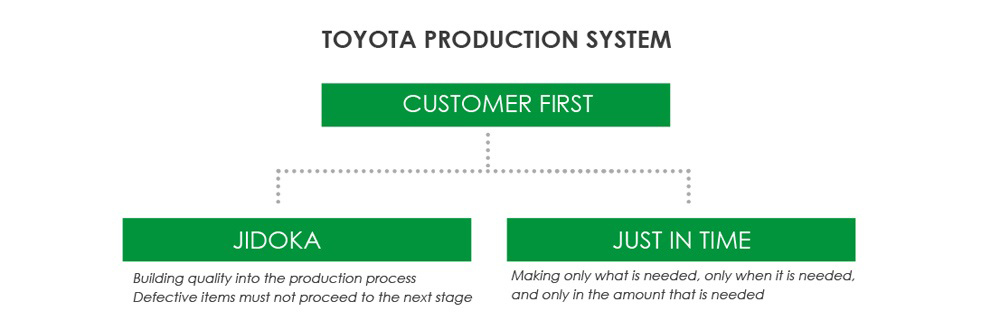

Quality is ensured in every vehicle that rolls out of Toyota Kirloskar Motor, through in-built audits at every process of the system. The company's operational excellence is based on the improvement tools and methods developed by Toyota under the Toyota Production System (TPS), greatly emphasizing superlative quality and minimal waste.

In line with Toyota's growing comfort with its India operations, the company set up Toyota Kirloskar Auto Parts (TKAP), which commenced production of transmissions in May 2004, for its global requirements. Another initiative is the Toyota Techno Park India (TTPI), a non-profit industrial infrastructure company aimed at boosting local industries and related job opportunities.

Setting benchmarks for the automobile industry, the manufacturing facility consists of 4 divisions (shops) - Press, Weld, Paint and Assembly.